In district heating and cooling applications, the choice of piping system plays a crucial role in efficiency, cost-effectiveness, and environmental impact. While single-pipe systems have long been the standard, twin-pipe systems are gaining traction due to their significant advantages. This article explores the key benefits of using twin-pipe systems over single-pipe systems in rigid pre-insulated pipe networks, focusing on capital expenditure (CAPEX) and operational expenditure (OPEX).

By Sabrina Fröhlich, Head of Marketing & PR, ISOPLUS Group, in collaboration with Jens Rasmussen, Head of Technical Department, ISOPLUS Denmark, and Karl Heinrich Schade, Sales Manager ISOPLUS Germany

Published in Hot Cool, edition no. 3/2025 | ISSN 0904 9681 |

Photo above: Twin pipe trench leading into the municipality of Rasdorf, Germany

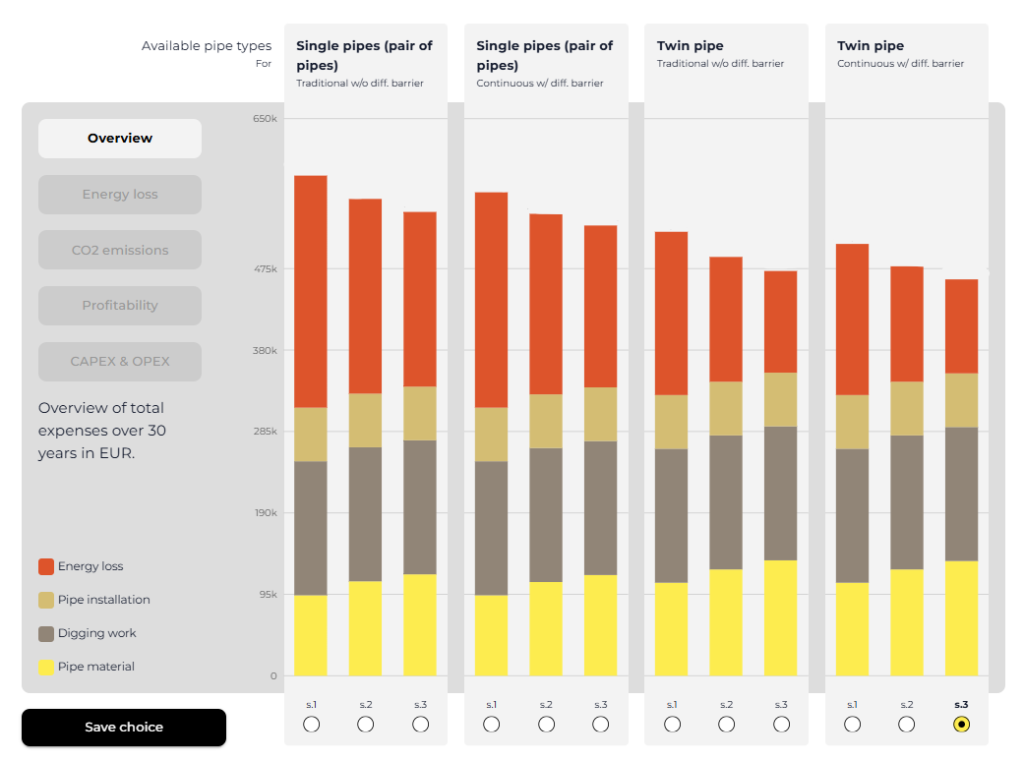

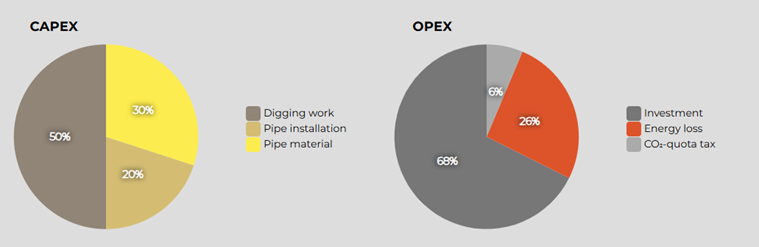

Total Cost of Ownership (TCO) perspective

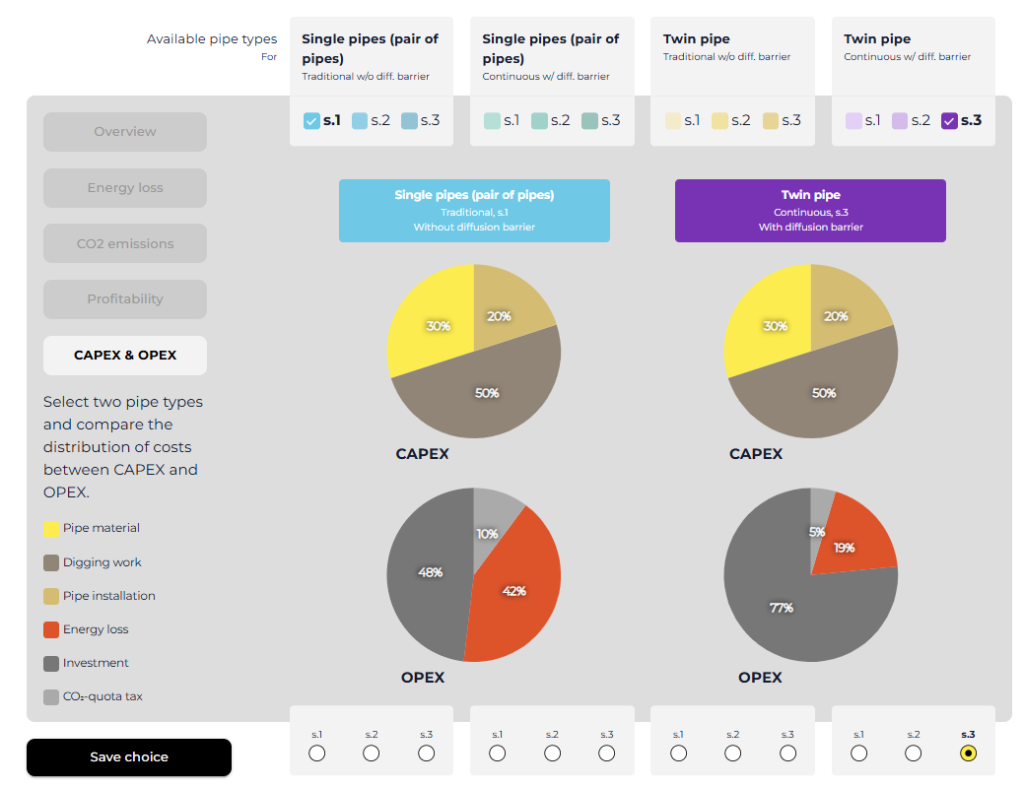

The selection of a pipe system should always be based on a Total Cost of Ownership (TCO) evaluation over a specified period, as determined by the stakeholder or asset owner. Compared to single-pipe systems, twin pipes provide significant advantages in capital expenditures (CAPEX) and operational expenditures (OPEX).

From a CAPEX perspective, twin pipes reduce product costs since fewer pre-insulated rigid pipes are required compared to single-pipe systems, necessitating fewer pipe elements. Additionally, civil installation costs are lower due to narrower trenches, which reduce excavation, re-establishment, and material expenses. Mechanical installation is also more cost-effective, as fewer casing joints are needed, simplifying the installation process.

Regarding OPEX, twin pipes minimize heat loss, offering the lowest possible heat losses compared to a pair of single pipes. They also require fewer maintenance and repairs because of the reduced number of casing joints, leading to lower ongoing operational costs.

Graphic 1: CAPEX & OPEX Comparison of a single pipe system series 1 to a twin pipe system series 3

Graphic 1: CAPEX & OPEX Comparison of a single pipe system series 1 to a twin pipe system series 3

Special features of twin pipes

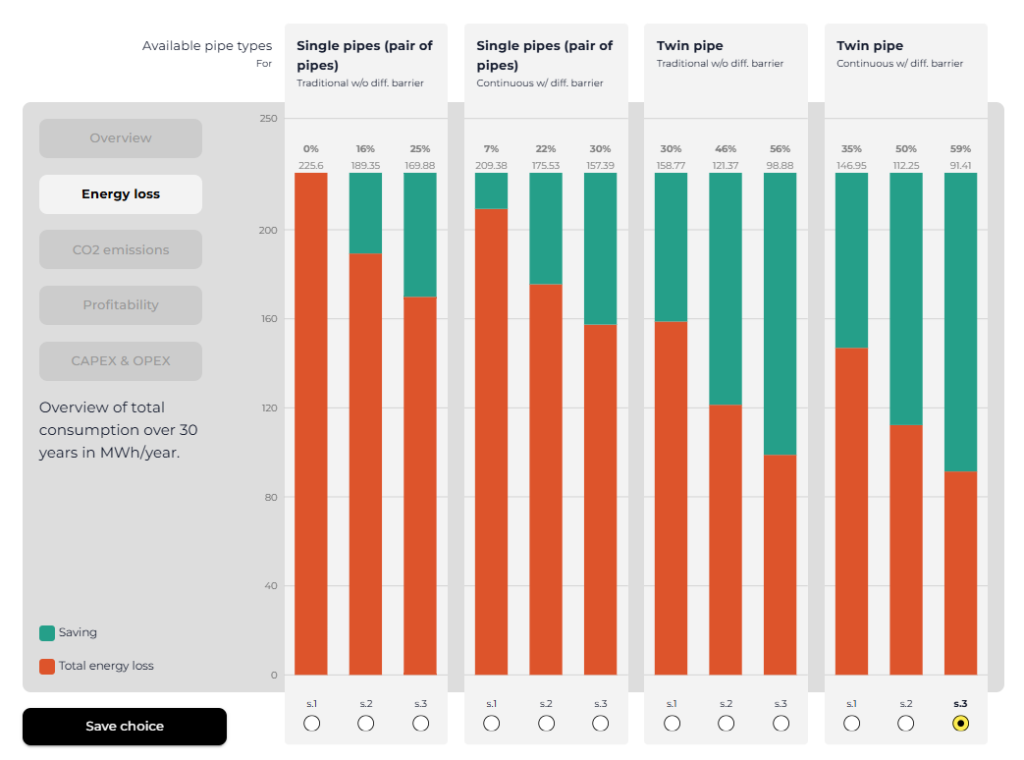

1. Enhanced thermal efficiency

One of the most compelling advantages of twin-pipe systems is improved thermal efficiency. Twin pipes house both the supply and return pipes within the same casing. That, when combined with optimal insulation geometry, reduces the overall heat loss compared to single pipe systems. Calculations show that twin-pipe systems can minimize heat loss by more than 30% compared to single-pipe systems, which translates to lower energy consumption and increased system efficiency.

Graphic 2: Comparison of thermal efficiency of all pipe systems. Overview of total consumption over 30 years MWh/year.

Graphic 2: Comparison of thermal efficiency of all pipe systems. Overview of total consumption over 30 years MWh/year.

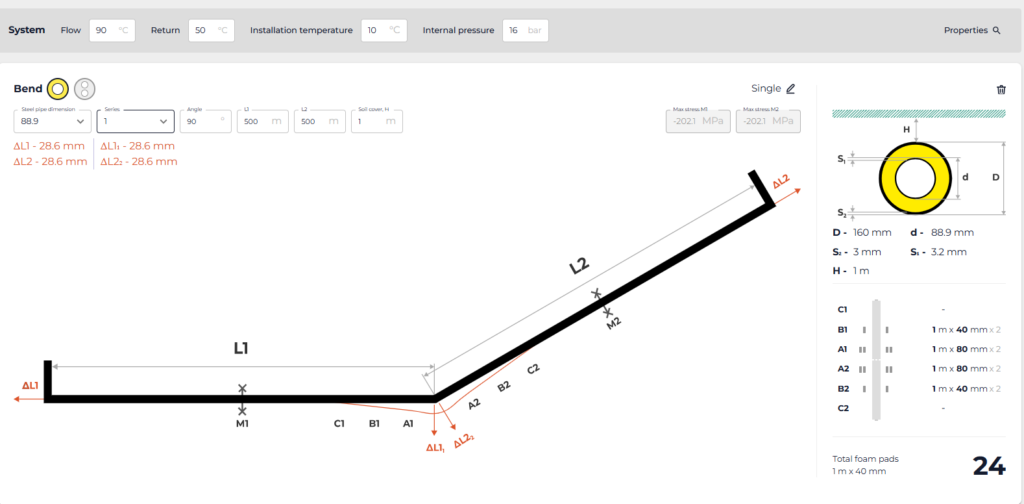

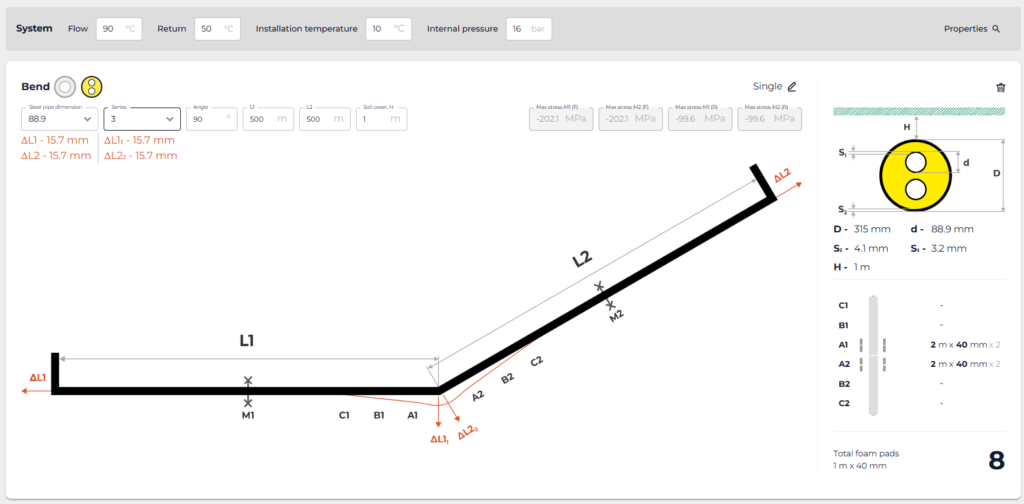

2. Less thermal expansion in the system

A twin pipe design reduces system expansion and contraction, enhancing stability and needing a less complex static design.

Graphic 3: Total amount of pipes and foam pads needed when using a single rigid pipe system.

Graphic 3: Total amount of pipes and foam pads needed when using a single rigid pipe system.

Graphic 4: Total amount of pipes and foam pads needed when using a twin rigid pipe system.

Graphic 4: Total amount of pipes and foam pads needed when using a twin rigid pipe system.

As the calculations in graphics 3 and 4 show, for the installation of a twin pipe system, in this specific situation, the bends were exposed to 13 mm less expansion (see red numbers) of twin pipes series 3 and 16 fewer foam pads were needed in comparison to the single pipe system.

3. Cost savings in installation and maintenance

A twin-pipe system reduces trenching and excavation costs by requiring less space in the trench. This significantly lowers labor and material costs associated with installation. The lower number of casing joints minimizes the risk of leaks, reducing maintenance costs over the system’s lifespan. Additionally, fewer casing joints help lower installation costs.

Graph 5: Overall profitability of a twin pipe system installation vs. Single pipe system installation over 30 years, reaching the break even after 11.2 years.

Graph 5: Overall profitability of a twin pipe system installation vs. Single pipe system installation over 30 years, reaching the break even after 11.2 years.

4. Faster installation

With narrower trenches and a more compact design, twin-pipe systems facilitate faster installation than single-pipe systems. This leads to shorter project timelines and reduced labor expenses. In large-scale district heating projects, this efficiency can translate into significant cost savings and quicker operational readiness.

5. Improved space utilization

In urban environments, space is often a constraint. Twin-pipe systems optimize space usage by requiring a narrower trench for flow and return lines, unlike single-pipe systems that necessitate wider trenches. This streamlined design is particularly beneficial in areas with limited underground infrastructure capacity.

6. Environmental benefits

By minimizing heat loss and reducing material usage, twin pipe systems contribute to lower carbon emissions and a smaller environmental footprint. The reduced excavation requirement also leads to less soil displacement and disruption to local ecosystems.

Graphic 6: CO2 Emissions reduction based on a project example in Rasdorf, Germany

Graphic 7: Comparison of single pipes vs. twin pipes solution in barre diagram based on the example of the project Rasdorf, Germany.

Graphic 7: Comparison of single pipes vs. twin pipes solution in barre diagram based on the example of the project Rasdorf, Germany.

Real-world implementation of twin pipe systems

The benefits of twin pipe systems are clearly demonstrated in several major district heating projects in Germany. One of them is the biomass-supported district heating network in Rasdorf, a municipality in the district of Fulda in eastern Hesse with around 1,600 inhabitants. This project shows how twin-pipe systems contribute to cost-effective, efficient, and sustainable energy distribution.

Rasdorf’s district heating network, powered by a woodchip boiler and an additional solar thermal system, is designed to supply 220 households. The system will replace approximately one million liters of heating oil annually, contributing to a CO₂-neutral community.

In summer, the solar thermal system will provide the heat, while five independent woodchip boilers cover the demand in winter and during peak loads. This combination saves approximately 3,000 tons of CO₂. Here, a total of 15,222 meters of twin pipes (DN25-DN150) series 3 from ISOPLUS ensures efficient heat transportation with minimized energy loss.

Twin pipe stock of pipes in Rasdorf, Germany

Twin pipe stock of pipes in Rasdorf, Germany

Additionally, with 70% of Rasdorf’s pipes installed in public areas, it is possible to install the system more easily and faster with minimal disruption, given the compact design of twin pipes. This reduces disturbance to citizens and minimizes the impact on traffic regulations, ensuring a more efficient and less intrusive installation process.

This is just one example to confirm the superiority of twin pipe systems in district heating projects, combining environmental benefits with economic advantages.

For a direct comparison of the choice of twin pipe installation over a single pipe system, the same parameters were introduced in a digital calculation tool isoCalc from ISOPLUS. isoCalc is one of the tools in a digital tools system, isoConnect, which helps to select the right pipe system and dimensions and insulation series, calculate heat loss, perform static calculations, and perform TCO.

Graphic 8: CAPEX/OPEX split for the project Rasdorf in Germany, comparing between a single pipe system and a twin pipe system

Conclusion

Adopting twin pipe systems in rigid pre-insulated pipe networks offers a range of advantages, from improved thermal efficiency to lower installation and maintenance costs. These benefits make them an increasingly attractive option for district heating and cooling projects worldwide. As urbanization and the demand for sustainable energy solutions continue to grow, the efficiency and practicality of twin-pipe systems will become even more vital in shaping the future of energy distribution.

For further information please contact: Jens Rasmussen, j.rasmussen@isoplus.dk

Why Choose Twin Pipes?

- Lowest possible heat losses compared to a pair of single pipes

- Narrower trench width, reducing excavation and civil costs

- Reduction in the number of casing joints required, cutting down installation costs

- Easier installation in transmission lines with minimal underground services

- Hybrid solution possible, combining twin and single pipes where applicable

“Twin Pipes Offering the Lowest Total Cost of Ownership” was published in Hot Cool, edition no. 3/2025. You can download the article here:

Did you find this article useful?

Subscribe to the HOT|COOL newsletters for free and get insightful articles on a variety of topics delivered to your inbox twice a month!