A business case for sharing investment and benefit

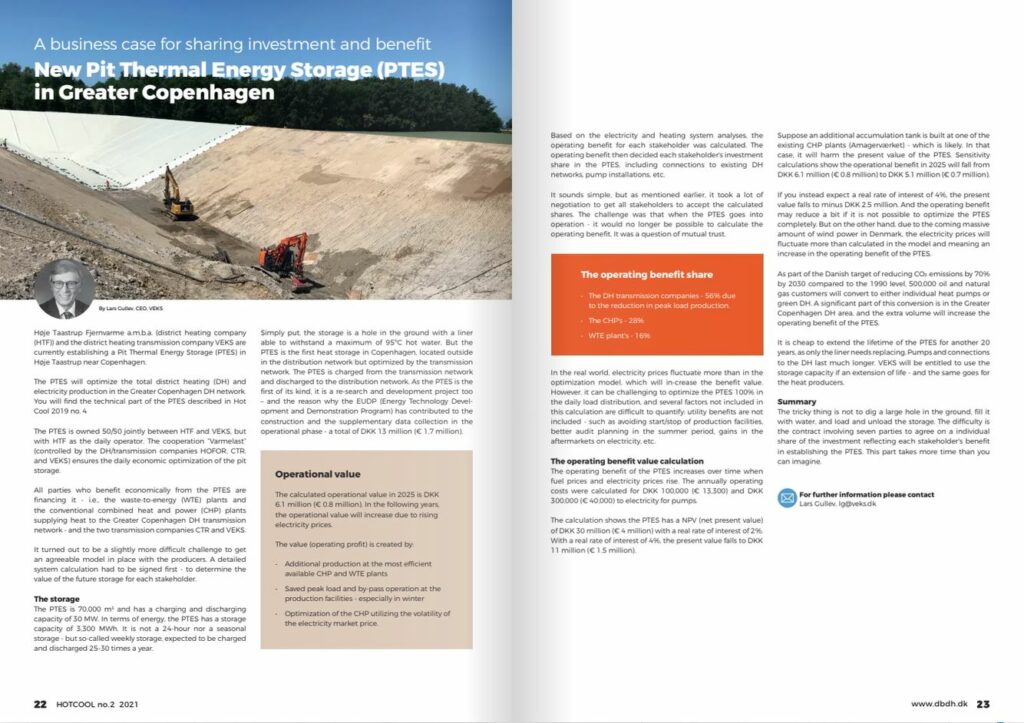

Høje Taastrup Fjernvarme a.m.b.a. (district heating company (HTF)) and the district heating trans-mission company VEKS are currently establishing a Pit Thermal Energy Storage (PTES) in Høje Taastrup near Copenhagen.

By Lars Gullev, CEO at VEKS

Published in Hot Cool, edition no. 2/2021 | ISSN 0904 9681 |

The PTES will optimize the total district heating (DH) and electricity production in the Greater Co-penhagen DH network. You will find the technical part of the PTES described in Hot Cool 2019 no. 4.

The PTES is owned 50/50 jointly between HTF and VEKS, but with HTF as the daily operator. The cooperation “Varmelast” (controlled by the DH/transmission companies HOFOR, CTR, and VEKS) ensures the daily economic optimization of the pit storage.

All parties who benefit economically from the PTES are financing it – i.e., the waste-to-energy (WTE) plants and the conventional combined heat and power (CHP) plants supplying heat to the Greater Copenhagen DH transmission network – and the two transmission companies CTR and VEKS.

It turned out to be a slightly more difficult challenge to get an agreeable model in place with the producers. A detailed system calculation had to be signed first – to determine the value of the fu-ture storage for each stakeholder.

The storage

The PTES is 70,000 m3 and has a charging and discharging capacity of 30 MW. In terms of energy, the PTES has a storage capacity of 3,300 MWh. It is not a 24-hour nor a seasonal storage – but so-called weekly storage, expected to be charged and discharged 25-30 times a year.

Simply put, the storage is a hole in the ground with a liner able to withstand a maximum of 95oC hot water. But the PTES is the first heat storage in Copenhagen, located outside in the distribution network but optimized by the transmission network. The PTES is charged from the transmission network and discharged to the distribution network. As the PTES is the first of its kind, it is a re-search and development project too – and the reason why the EUDP (Energy Technology Develop-ment and Demonstration Program) has contributed to the construction and the supplementary data collection in the operational phase – a total of DKK 13 million (€ 1.7 million).

Operational value

The calculated operational value in 2025 is DKK 6.1 million (€ 0.8 million). In the following years, the operational value will increase due to rising electricity prices.

The value (operating profit) is created by:

- Additional production at the most efficient available CHP and WTE plants

- Saved peak load and by-pass operation at the production facilities – especially in winter

- Optimization of the CHP utilizing the volatility of the electricity market price.

Based on the electricity and heating system analyses, the operating benefit for each stakeholder was calculated. The operating benefit then decided each stakeholder’s investment share in the PTES, including connections to existing DH networks, pump installations, etc.

It sounds simple, but as mentioned earlier, it took a lot of negotiation to get all stakeholders to ac-cept the calculated shares. The challenge was that when the PTES goes into operation – it would no longer be possible to calculate the operating benefit. It was a question of mutual trust.

The operating benefit share

- The DH transmission companies – 56% due to the reduction in peak load production.

- The CHP’s – 28%

- The WTE plant – 16%

In the real world, electricity prices fluctuate more than in the optimization model, which will in-crease the benefit value. However, it can be challenging to optimize the PTES 100% in the daily load distribution, and several factors not included in this calculation are difficult to quantify: utility benefits are not included – such as avoiding start/stop of production facilities, better audit planning in the summer period, gains in the aftermarkets on electricity, etc.

The operating benefit value calculation

The operating benefit of the PTES increases over time when fuel prices and electricity prices rise. The annually operating costs were calculated for DKK 100,000 (€ 13,300) and DKK 300,000 (€ 40,000) to electricity for pumps.

The calculation shows the PTES has a NPV (net present value) of DKK 30 million (€ 4 million) with a real rate of interest of 2%. With a real rate of interest of 4%, the present value falls to DKK 11 mil-lion (€ 1.5 million).

Suppose an additional accumulation tank is built at one of the existing CHP plants (Amagerværket) – which is likely. In that case, it will harm the present value of the PTES. Sensitivity calculations show the operational benefit in 2025 will fall from DKK 6.1 million (€ 0.8 million) to DKK 5.1 million (€ 0.7 million).

If you instead expect a real rate of interest of 4%, the present value falls to minus DKK 2.5 million. And the operating benefit may reduce a bit if it is not possible to optimize the PTES completely. But on the other hand, due to the coming massive amount of wind power in Denmark, the electricity prices will fluctuate more than calculated in the model and meaning an increase in the operating benefit of the PTES.

As part of the Danish target of reducing CO2 emissions by 70% by 2030 compared to the 1990 level, 500,000 oil and natural gas customers will convert to either individual heat pumps or green DH. A significant part of this conversion is in the Greater Copenhagen DH area, and the extra volume will increase the operating benefit of the PTES.

It is cheap to extend the lifetime of the PTES for another 20 years, as only the liner needs replacing. Pumps and connections to the DH last much longer. VEKS will be entitled to use the storage capaci-ty if an extension of life – and the same goes for the heat producers.

Summary

The tricky thing is not to dig a large hole in the ground, fill it with water, and load and unload the storage. The difficulty is the contract involving seven parties to agree on a individual share of the investment reflecting each stakeholder’s benefit in establishing the PTES. This part takes more time than you can imagine.

For further information, please contact: Lars Gullev, at lg@veks.dk