Efficient DHN technology, including heat loss

Most technologies used for individual heating can also produce heat delivered to district heating systems. Today, the most common technologies for individual heating are boilers and heat pumps.

By John Tang Jensen, District Energy Senior Advisor

Large boilers in district heating systems typically perform better than individual boilers due to low-temperature flue gas exchangers and flue gas condensers, making them around 5 – 10% better than individual solutions.

When the heat losses in the district heating system are included, then boilers established in district heating systems do not, from an efficiency point of view, perform better than individual heating solutions, and this is the reason for only using boilers in district heating systems for peak load purpose or if the used fuel is much cheaper when delivered to district heating companies compared to delivery to individual buildings.

Large-scale boilers in district heating might not be significantly more efficient but can achieve lower overall maintenance costs. Only one unit needs to be maintained instead of many individual units.

When it comes to large-air-to-water heat pumps compared to individual air-to-water heat pumps, the performance is, in the worst cases, on the same level as individual heat pumps and, in best cases, more than 20% better than individual. When the district heating heat pumps use waste heat sources unavailable for individual heat pumps with higher temperatures than air, the heat pump performance is significantly better. Then, in general, district heating heat pumps, including heat loss in the network, are more efficient than individual heat pumps. See Table 1 below.

Regarding investments, an individual boiler and a heat pump are almost twice more expensive per kW-heat than a district heating boiler or heat pump.

Technical Data for Heating Technologies

| UK Prices | Individual Sources | DH Technologies | Difference | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Data from Danish technology catalogue | Gas Boiler | HP Air-Water | Gas Boiler | HP Air-Water (1MW) | HP Air-Water (3MW) | HP Air-Water (10MW) | Boiler | Large heat pump | |

| Heat Capacity | MW | 1000 | 1000 | 1000 | 1000 | 3000 | 10000 | – | – |

| Average Heat Efficiency | – | 97% | 315% | 103% | 290% | 340% | 380% | 6% | 21% |

| Technical Lifetime | Years | 20 | 16 | 25 | 25 | 25 | 25 | 25% | 56% |

| Total Investment | M£/MW heat | 0.24 | 1.33 | 0.05 | 1.22 | 0.81 | 0.731 | -98% | -92% |

| Variable O&M Total | £/MWh heat | 0 | 0 | 0.94 | 2.29 | 1.86 | 1.69 | – | – |

| Fixed O&M Total | €/MW-heat/year | 11657 | 37764 | 1658 | 1700 | 1700 | 2000 | 916% | 666% |

Table 1: Technology data heating technologies (Individual heat pump for same forward temperature as district heating)

Reducing extra individual capacity

When having individual heating systems, the installed boiler or heat pump needs to cover the heat demand on the coldest day and during the peak load hour, when most energy is used to heat the building and provide hot tap water. The boilers and heat pumps used are normally produced in standard sizes fitting to building demand, including hot tap water, which is often oversized compared to building demand.

When district heating capacity is designed, the needed heat production capacity will be pretty low compared to individual capacity because each dwelling does not have peak load demand at the precisely same time and because the daily peak load demand often can be covered either by accepting a decrease of the forward temperature, by increasing forward temperature 2-3 hours before expected daily peak load and/or by having a storage tank as a part of the heat production plant.

Reducing capacity demand

District heating technology can save fuels and investments in production capacity. On average, the peak load demand for district heating systems is 30 – 60% lower per dwelling than individual solutions, even when the capacity additionally needs to cover heat network losses.

Reducing costs by classic design

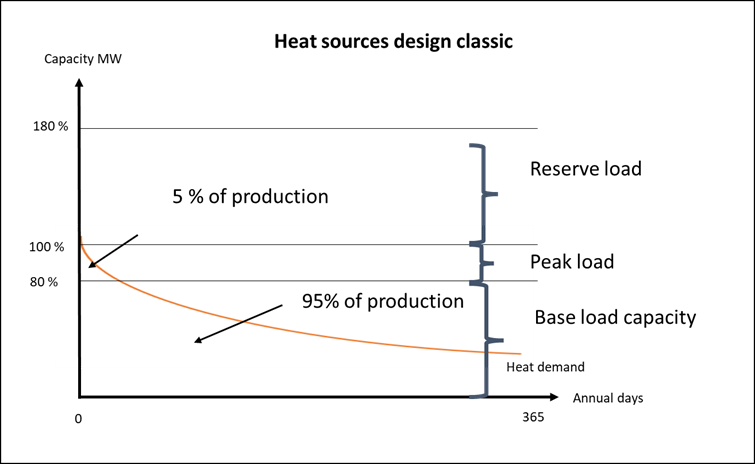

Figure 2 shows an important design principle. When the demand curve is established, the last 20% to 30% of heat production capacity demand often only covers around 5% of production demand.

From an investment point of view, it would be better to establish a base load capacity that covers around 70 – 80% of capacity demand and use cheap boiler technology for peak-load demand and reserve load capacity.

Figure 2: Classic heat source design

Investments can then be saved further if technologies are combined to optimize investments. If, for example, the base load capacity of 80% in Figure 2 is divided between 2 units, covering 40% of capacity demand, the reserve load capacity can then be reduced to 40%. Suppose heat storage is installed to level out production during the day and remove the direct connection between heat demand and production, which saves maintenance costs. In that case, the storage capacity can replace the need for peak load capacity, reducing the overall investments in peak and reserve load.

Avoiding curtailment of electricity by design of heat sources and storage

When the capacity and production of electricity from wind turbines and solar PV start to dominate power market pricing in an increasing number of hours each year, renewable power production may exceed the demand and even exceeds the possibility of exporting the electricity to neighbouring price areas. Then, society may need to accept that the electricity production from these renewable sources must stop and be curtailed. If the electricity is subsidized or the plants have made fixed price arrangements, they may not stop even if the power price is negative, and then the regulator must pay the power production units to stop.

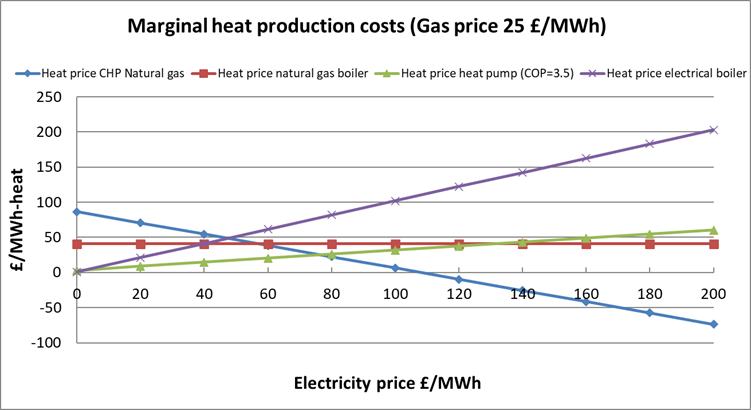

Figure 3: Marginal heat production prices with a variable gas price of 25 £/MWh

In Figure 3, an electric boiler is added to the heat source design of a district heating company. This electric boiler can be a peak load resource for the heat side in wintertime. Still, the value of an electric boiler is much larger when it comes to being a reserve load for the power market because this boiler can consume the power that otherwise would have been curtailed or exported out of the system without any local tariff payment for transportation. As shown in Figure 3, the point of action of the electric boiler is close to zero compared to the heat pump, and the main reason for this is that the economic value of using an electrical boiler is earned by the electricity grid company getting paid for transportation that otherwise would have been curtailed. If this value could be shared between the heat and electricity grid companies, the electric boiler would come into action with a slightly higher electricity price and make the investment feasible for the district heating company due to the increased running hours.